3D Scanning

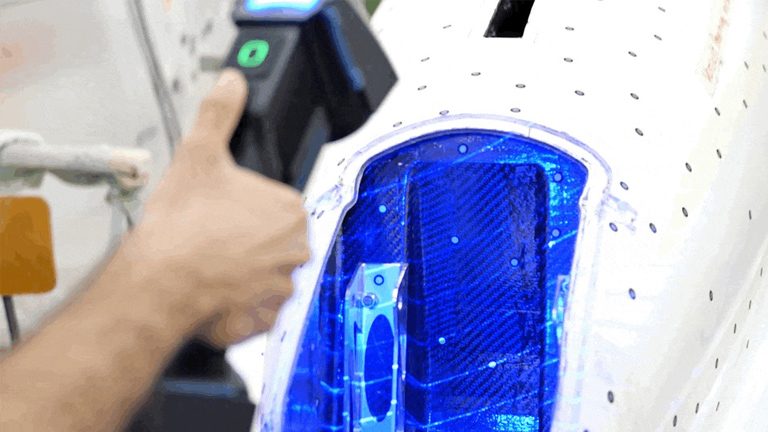

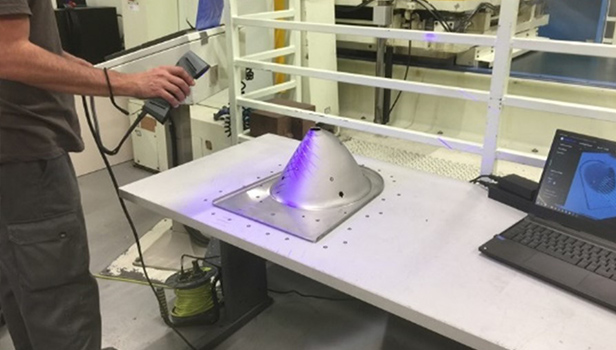

3D scanning is an advanced technology that allows you to capture the shape and dimensions of a physical object, transforming it into a three-dimensional digital model.

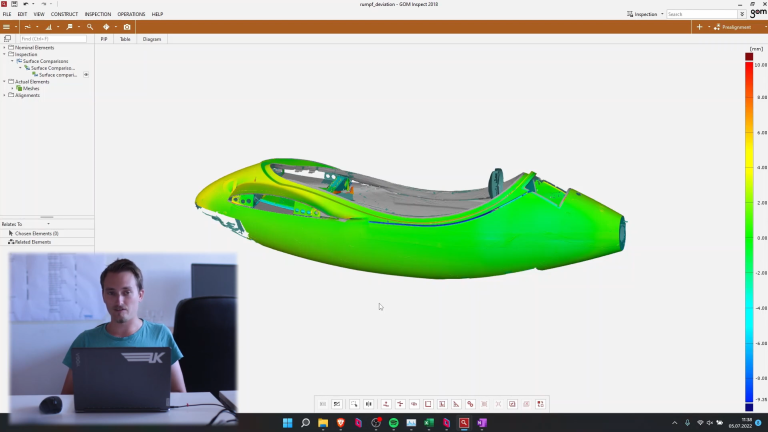

Through subsequent processing, a polygonal mesh is generated that represents the shape of the object on the scanned surface, with the possibility of also capturing the texture to obtain color scans.

The file obtained from the 3D scan can be provided in the most common formats (STL, OBJ, PLY, 3MF, P3) to be directly 3D printed.

The primary goals of 3D scanning include:

- Capture precise details: Get an extremely accurate representation of the object, capturing even the smallest details.

- Efficiency in the digitization process: Reduce the time and cost required to convert physical objects into digital models.

- Facilitate analysis and manipulation: Create 3D models that can be easily analyzed, modified and integrated into various digital processes, such as CAD design, simulation or augmented reality.

- Digital Preservation: Providing a durable digital copy of objects of historical, scientific or cultural value, ensuring their preservation for future generations.

- Production and customization support: Enable the production of customized components and the quality verification of finished products through comparisons with original design models.

These goals make the technology powerful and versatile, capable of improving efficiency and precision in multiple sectors.

Reverse Engineering

Reverse engineering is a process that allows you to create a parametric and editable digital model of the scanned object, in order to obtain a three-dimensional project file or to modify an existing one to improve its appearance and functionality. At the end of the process, a STEP file is generated that can be used in CAD software.

Applications:

- Maintenance and repair: Reproduction of hard-to-find components.

- Optimization: Improvement of existing design.

- Documentation: Creation of detailed technical documentation of existing objects.

- Rapid prototyping: Creation of prototypes for testing and development.

SECTORS

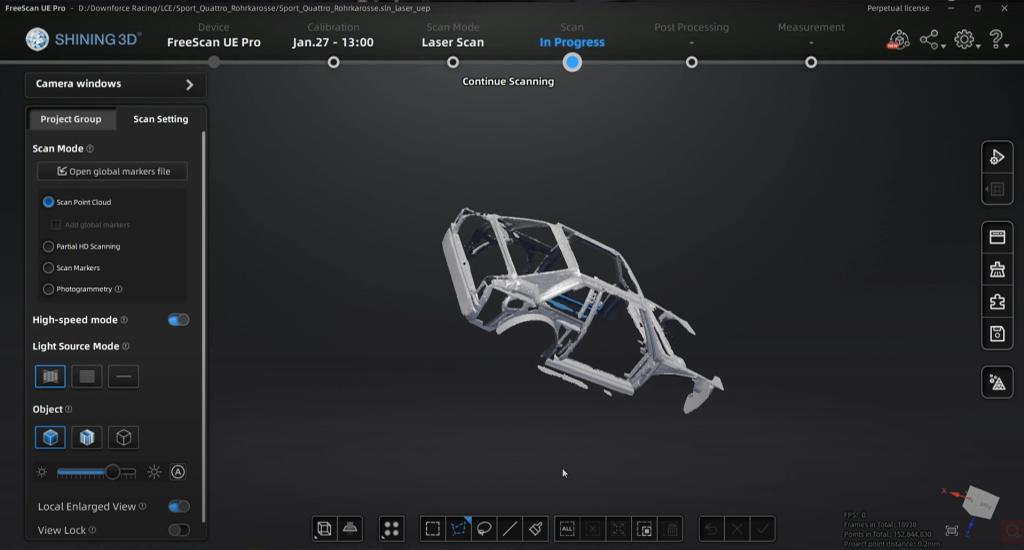

AUTOMOTIVE

In the automotive sector, there are several applications of 3D scanning; for example, scanned 3D models can be used to create prototypes with 3D printers, speeding up the design and development process of new products. Another application is the verification of the assembly of complex parts such as engines. Scans can be used to ensure that all components are positioned correctly and that there are no interferences between moving parts. Another example is the optimization of vehicle aerodynamics. Scanned 3D models can be used in computer simulations to analyze and improve the airflow around the vehicle, reducing drag and improving energy efficiency. Finally, it allows to verify that the finished products exactly match the design specifications, detecting defects or deviations from expected tolerances.

Every special vehicle, such as emergency, transportation or police vehicles, ambulances, or fire trucks, must be equipped with special equipment and setups designed specifically to meet each specific need. 3D scanning is useful for gathering all the information and having documentation on specific areas of the vehicles on which to design equipment.

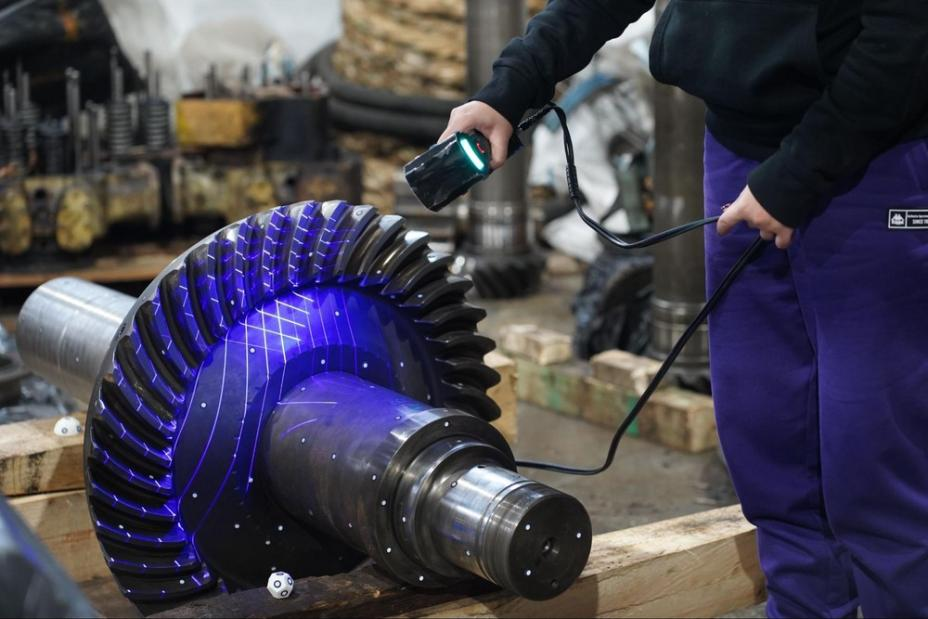

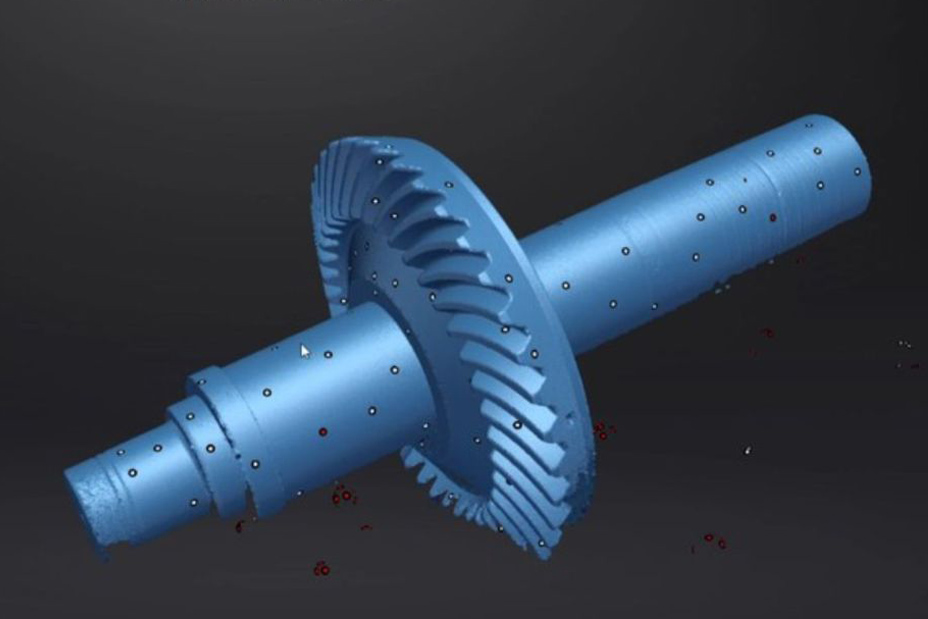

NAVAL

An example of 3D scanning integration in the naval field is that of ship maintenance. Ship maintenance plays a crucial role in ensuring the safety, transportation efficiency and longevity of vessels. Traditional methods of assessment and repair often involve manual measurements, drawings and physical prototypes. However, with the advancement of technology, there has been a significant shift towards more precise, efficient and cost-effective maintenance practices.

For example, rotating gears, which often have complex profiles, internal bores, and threads, are difficult to measure with manual systems. Additionally, their size and weight make them difficult to handle and manipulate accurately during the repair process. These limitations highlight the need to adopt advanced technologies such as 3D scanning for a more efficient and accurate approach.

AEROSPACE

In the aerospace industry, 3D scanning is very useful if you need to perform quality control operations or to facilitate future design processes. An example is a glider with an unusual shaped fuselage, with curved surfaces and is difficult to measure in a traditional way; 3D scanning is useful to quantify deviations for future replacement of parts.

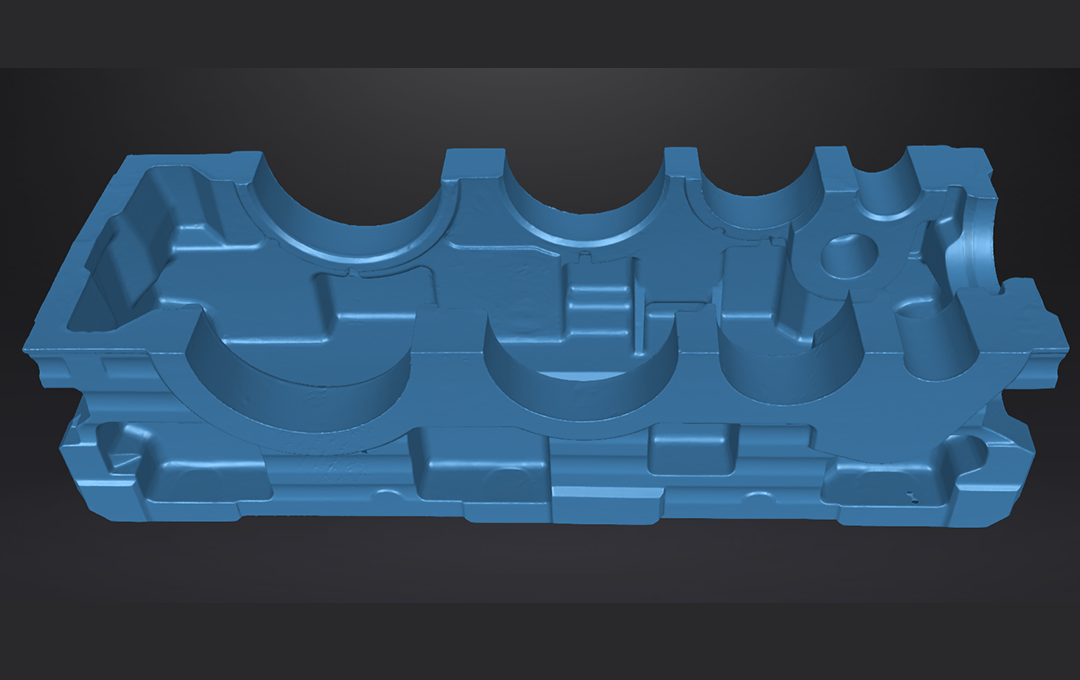

MECHANICS

In the production of automotive body components, such as molds, there are stringent requirements for the entire surface profile. Therefore, it makes sense to capture the surface as a whole through 3D scanning.

Sheet metal inspection also has strict requirements for the quality of the final product.

Cast components are subject to deformation due to high temperatures. For this reason, before being delivered to the end customer, it may be necessary to perform a dimensional check to generate an inspection report on the product. This process requires a 3D scan upstream.

ART & DESIGN

Restorers use 3D scanning to create digital copies of historical artifacts, thus preserving details that could be lost over time. 3D models can be used to simulate the restoration of works of art and ancient structures.

MEDICAL

3D scanning is used to create custom-made prostheses and implants that are perfectly adapted to the patient's morphology. 3D models of organs and anatomical structures can help surgeons plan complex interventions with greater precision.

FASHION / FOOTWEAR

Technology is also spreading lately in the fashion and footwear industry due to the needs of designers and companies. In this context it is convenient to obtain a 3D digital model for future production or modifications, or to create a custom product for the customer, such as a shoe or a dress. A fashion designer can scan a mannequin or a person to create a 3D model on which to develop new garments. This allows the design to be visualized and digitally modified, optimizing the fit and style before production.