PEEK and ULTEM: new materials available for Fast Parts

A recent survey by us has highlighted the growing demand for high-performance polymers, for ever more specific applications.

While almost all of the requests refer to standard or reinforced technopolymers, which can be processed by most of the professional desktop FDM printers on the market, there is also a growing interest in high-performance polymers that should operate in critical situations (high temperatures, radiation, high stresses).

Among these, PEEK and ULTEM.

PEEK is a semi-crystalline thermoplastic material, considered a technopolymer due to its highly performing characteristics. In fact, this material has high mechanical resistance to wear, high temperatures, chemical agents and radiation, which make it ideal for specific applications in the Aerospace, Automotive, Electronics, Oil&Gas and Medical sectors.

ULTEM 9085 is to be considered a high performance self-extinguishing thermoplastic ideal for the transport, aerospace sector, thanks to its high strength/weight ratio and FST certification (flame, smoke, toxicity). It is also suitable for functional tests in extreme conditions that require high performance, resistance to chemical agents and high temperatures.

ULTEM 9085 is the most used material in 3D printing for metal replacement.

The 5 main differences affecting the choice between PEEK and ULTEM

Heat resistance

PEEK has a melting temperature of 370°C and allows the use of 3D printed components, without deformation, at constant temperatures of 260°C. From this point of view, ULTEM is more deficient, presenting deformations at low loads at temperatures close to 180°C.

Processability

After printing, PEEK requires an annealing heat treatment in the oven for about 3 hours, ULTEM does not require post-processing or heat treatments.

Chemical resistance

Both polymers have high characteristics in terms of resistance to solvents, but PEEK is uniquely distinguished by being dissolvable in sulfuric acid.

Wear resistance

PEEK has higher frictional resistance than ULTEM.

Cost

The biggest difference between the materials, however, remains the cost.

PEEK is the most expensive polymer on the market, and ULTEM offers fairly similar properties, at a lower price.

PEEK and ULTEM manufacturing

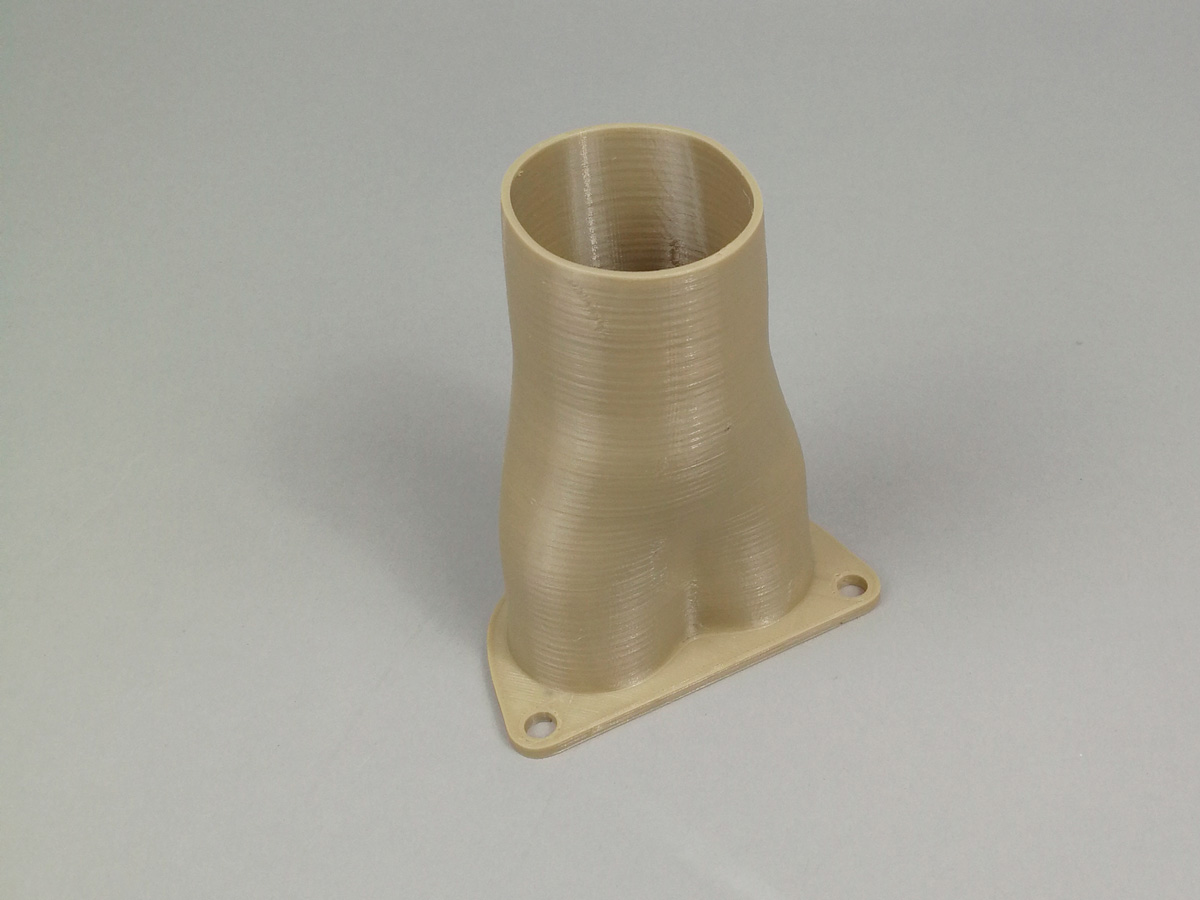

From today Fast Parts can also satisfy these requests, thanks to the installation of the new INTAMSYS 3D printers for the processing of these particular polymers.